Jump like a Grasshopper

Freiburg, Mar 19, 2019

Konrad Lorenz was trying to be nice when he told humans not to worry about losing their place as the crown of creation to gazelles, monkeys, and dolphins. The legendary zoologist and expert in animal behavior assured humans they could easily beat all three animals if they all competed in a triathlon of running, climbing, and swimming. While that’s reassuring, it would also be nice if humans could jump like grasshoppers, right? Dr. Stefan Schiller from the Center for Biosystems Analysis (ZBSA) at the University of Freiburg is working on just that.

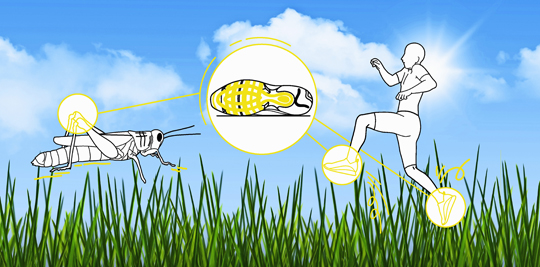

Farther, higher, faster: Tennis shoes with a sole made of an elastic protein produced by grasshoppers could one day help humans break many world records in sports. Illustration: Svenja Kirsch, Photo: Winyu/stock.adobe.com

“If you translate it into human terms, the insect is able to jump a distance of about 200 meters,” Stefan Schiller said. He once calculated this for a Science Slam, where he presented his work as a specialist in bionic chemistry and synthetic nanobiology by entertaining the audience. The grasshopper is an example of Schiller’s current research at the new excellence cluster Living, Adaptive and Energy-autonomous Materials, or livMatS, whose primary goal is to develop new materials based on nature. Schiller has found inspiration in grasshoppers and fleas. These insects have something scientists call “mechanically active material systems with extreme characteristics for demanding functions.” In the comic world of Spider-Man, Ant-Man, and The Wasp, we could say they have “superpowers.”

Schiller prefers the term “ultra qualities.” The grasshopper’s ultra qualities are located in its hind legs, where a protein produced in its body called resilin can be found. This protein is almost completely elastic, which means that virtually all mechanical energy input gets released. If we had tennis shoes with a sole made of resilin, we could jump higher every time we touched the ground. At the Science Slam, Schiller joked that one day travel agencies may have a new business offering jumps over the Black Forest instead of flights.

Custom-made materials

While the tennis shoes aren’t ready for the market just yet, they may be a reality in the not-too-distant future. When Schiller first began his research, there were few available methods for customizing protein sequences to produce proteins with the desired qualities. Proteins are complex constructions: Not only the composition of folding but also the type affects the qualities. That’s why Schiller and his colleagues established a library in which they can catalog protein sequences according to length, possible combinations, and qualities. Researchers can now use this library for applying new technologies in different combinations to customize large numbers of complex molecules taken from genetically modified cells into mechanically active material microstructures to which they can assign virtually any 3-D structure. Schiller won an award from the Federal Ministry for Education and Research in 2014 for the development of this next generation of biotechnological methods. The Baden-Württemberg Stiftung is funding the ongoing material research.

These new methods can now be used not only to produce new materials with ultra qualities, but to alter their internal structure to create so-called meta-materials. The idea is that these meta-materials should be able to react to environmental influences, like changes in temperature or humidity, in addition to their other qualities, such as ultra elasticity. That’s what the excellence cluster livMatS is referring to when it talks about “adaptive.” “A change in qualities due to humidity would not be useful for the ultra-elastic tennis shoe, but for insulation materials, it would make sense,” Schiller said. Scientists are now talking about 4-D and 5-D materials that could react autonomously to environmental stimuli and perform movements under certain conditions that would otherwise require machines, thanks purely to their qualities.

Biologically produced and biodegradable

“This brings us to the aspect of sustainability, which is another central component of livMatS,” Schiller said. The goal is for material cycles to rely on biological processes as much as possible. A classical economic approach would be to produce ultra-elastic shoes by building a machine that transforms the jumping legs of grasshoppers into jumping shoe soles using huge amounts of fossil fuels. Schiller’s approach is different and begins with identifying the protein sequence needed for the ultra quality. The grasshopper’s resilin would be unnecessarily complex for this purpose.

The simpler protein elastin, which can also be found in human skin, would be more suitable, and it can be produced biologically in large amounts by modified cells. The next step is to extract the right sequences and structural elements, combine them as desired, and translate them into a genetic code that can be fed to cells so that they can produce the desired material.

The production of materials is therefore a biological process. The protein-based end product is also biological and can degrade in natural material and energy cycles. Such material cycles represent a huge step toward freeing ourselves from fossil fuels in the future. And who knows, like in comic books, Schiller’s research may one day mean that we can hop around like oversized grasshoppers on “seven-league soles” that leave no carbon footprint and let us reach our vacation destinations by taking gigantic leaps.

Jürgen Reuß