Against Peatland Loss

Freiburg, Sep 28, 2020

In the laboratory of Prof. Dr. Ralf Reski peat mosses grow. In the future, these will be used for the cultivation of seedlings in vegetable and ornamental plant production. What currently works in the bioreactor is intended to form the basis for the production of large quantities to replace the peat used so far in commercial cultivation. In this way, peatlands, from which peat has so far come, can be saved as important CO2 reservoirs.

Research on sustainable peatland management is important for the climate, because peatlands have much more CO2 sequestered in their moss than all of the world’s forests together. Photo: Greta Gaudig

Research on sustainable peatland management is important for the climate, because peatlands have much more CO2 sequestered in their moss than all of the world’s forests together. Photo: Greta Gaudig

If you want to save the climate, you should also take a look at peatlands. “They have much more CO2 sequestered in their moss than all the world’s forests together,” says Prof. Dr. Ralf Reski from the University of Freiburg’s Department of Plant Biotechnology. But peatlands worldwide are threatened by peat extraction. “We all use peat, directly or indirectly,” explains senior lecturer Dr. Eva Decker from Reski’s research group: “There’s currently no alternative to peat for growing vegetables under glass.” There is as yet no method of cultivation that is capable of conserving peatlands: There’s a lack of seeds for peat moss, and the moss grows too slowly in the open. In the MOOSzucht research project, Reski’s team has now succeeded in increasing the seed yield by a factor of 50 to 100 in the lab. “That is the foundation for sustainable peatland management,” says doctoral candidate Melanie Heck. The peat moss from Reski’s lab also promises a higher yield.

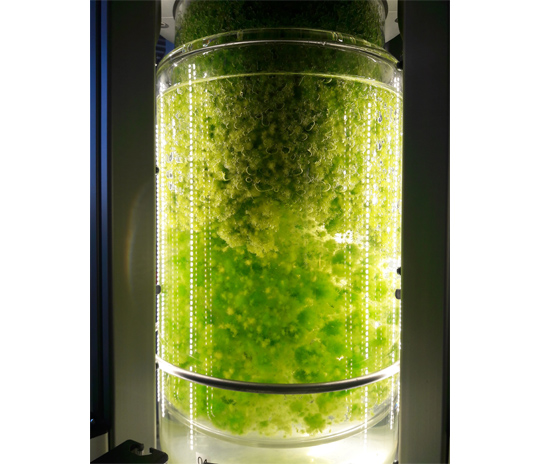

Cultivation in a bioreactor

“We can do mosses,” says Reski as a way of summing up the expertise of his team of around 30 researchers. They cultivated the spreading earth moss Physcomitrella patens in a bioreactor and were instrumental in sequencing its complete genome. The team has established mosses as model organisms in research and discovered new signaling paths, regulation mechanisms, and economically interesting genes. The plant biotechnologist is a cofounder of Greenovation Biotech GmbH, a company that produces proteins for drugs in moss bioreactors: “One of them has already successfully completed the clinical phase I study.”

Sphagnum in the bioreactor: A Freiburg team is studying peat mosses. Photo: Melanie Heck

Sphagnum in the bioreactor: A Freiburg team is studying peat mosses. Photo: Melanie Heck

In the MOOSzucht project, Reski and his colleagues from the Institute of Botany and Landscape Ecology at the University of Greifswald aim to prepare the ground for profitable peat cultivation. That will involve increasing the productivity of peat mosses by at least 30 percent. The Greifswald researchers asked the Freiburg biologists: “Can you also cultivate Sphagnum in a bioreactor?” That’s the name of the genus of peat mosses. “They are poorly researched,” says Reski. In the lab, Sphagnum has been relegated to the sidelines for decades. Even the number of species is uncertain, with experts estimating it at anything from 150 to 450. But Reski’s research group had already cultivated a Sphagnum species in a bioreactor for the European research consortium MOSSclone. These mosses will soon be used as passive sensors to monitor our air quality.

Peatlands as a Climate Protector

In white peat, the principle peat product, moss serves other purposes: White peat can absorb up to twenty times its weight in water. It does not secrete any substances, so all possible conditions in the environment can be set as desired. “It’s ideal for raising all kinds of seedlings,” explains Decker, the project manager in the lab. Most seedlings for flowers, vegetables, and lettuces sprout in white peat, whether private or commercial, conventional or organic. Germany alone consumes three million cubic meters a year. Producing such a large amount of wild peat moss would require vast expanses of land. “Wild peat moss grows very slowly,” says Decker, “only a centimeter a year.”

Global consumption of peat amounts to 30 million cubic meters, and this peat comes from peatlands. The extraction represents a heavy blow to the peatlands. “The peat doesn’t grow back,” says Decker. Germany has largely banned peat extraction, “but there are no viable alternatives to peat.” The extraction companies have therefore moved their operations away, for instance to Eastern Europe. The loss of peatlands is highly detrimental to the climate. “Mosses absorb nutrients and many pollutants from the environment via their surface,” explains the researcher. Peatlands are around 20 times more effective than forests at protecting the climate: While forests cover around 30 percent of the global land and freshwater surface, peatlands account for a mere 3 percent, but they bind twice as much CO2. What’s more, plants like sundews and several orchid species grow exclusively in peatlands.

Under favorable conditions in the bioreactor, some species and their spores reproduce 50 to 100 times faster than in peatland. Photos: Anja Prager, Greta Gaudig

Under favorable conditions in the bioreactor, some species and their spores reproduce 50 to 100 times faster than in peatland. Photos: Anja Prager, Greta Gaudig

The task of producing more Sphagnum seeds fell to the doctoral candidate Heck. Her job involved cultivating 20 species in a bioreactor for the first time for MOOSzucht: “It was a very time-consuming process to establish axenic cultures.” These pure cultures contain only a single species of moss – no other species and no bacteria, fungi, algae, or other living things. Heck therefore had to begin by freeing the little plants from all other organisms in the field. Then one Sphagnum species refused to grow in the reactor at all, while another developed only poorly over the course of a year. This drove Heck to optimize the conditions for growth: “I tested each of eight components in the medium on three settings.” This led to the disqualification of three ingredients that had no effect on growth. Heck tested all of the others in further concentrations and combinations. She also varied the temperature and the light dosage. In the end, six species turned out to be excellent seed producers: Under favorable conditions in the bioreactor, they and their spores reproduce 50 to 100 times faster than in peatland.

“That was a design experiment, not a matter of guesswork,” stresses Reski. The measurements from the experimental series were also integrated into simulation models. This reduces costs while increasing efficiency. “In economically oriented projects like MOOSzucht, we also have to consider costs and practical suitability,” says Reski. He is thus all the more pleased that Heck’s laboratory mosses grow in paludicultures – on wet peatland soils in the open air.

Reintroducing Species without Risks

Another branch of MOOSzucht in Reski’s lab involves improving the growth rate of peat mosses by means of smart Sphagnum breeding. SSB, as it is called for short, is basically turbo breeding: Instead of waiting for the moss to reproduce naturally at its own slow pace, the researchers mix in cells from Sphagnum plants with favorable properties. The aim is to double all genes, including the favorable genes. “Such mosses contain exclusively genes that belong to the species. They are not genetically engineered,” clarifies project manager Decker. The reintroduction of the species thus presents no risks.

The funding period for MOOSzucht ends in May, but Reski hopes to receive an extension for the project, on which two groups from the University of Greifswald, the Karlsruhe Institute of Technology (KIT), the company NIRA GmbH & Co. KG, and his own team are collaborating: “We would like to measure over the course of a year how much more biomass our peat mosses produce in paludiculture.” That would bring Heck closer to realizing her scientific dream: “I would be delighted if my mosses could save peatlands and help the climate.” Decker and Reski are dreaming in several directions: “I would also wish that one of the human proteins that we produce with mosses in the bioreactor is one day approved as a biopharmaceutical and helps people,” says Reski. And Decker already has a particular protein in mind: “I hope Faktor H is the one to do it.” He sees this particular factor as having good prospects for one day helping patients with rare kidney diseases and those with the widespread eye condition age-related macular degeneration.

Jürgen Schickinger