Buckling as a technical revolution

Freiburg, Aug 19, 2019

Micropumps and microvalves pump, administer dosages, and cool the liquids in infusions, printing processes, electrical equipment and in countless industrial processes. Ardavan Shabanian, a researcher from Freiburg, has revolutionized the design principle of miniature devices to such an extent that they are more compact, more powerful, more economical and more robust. His fledgling start-up company muVaP has received one of the largest EXIST grants to date at the University of Freiburg.

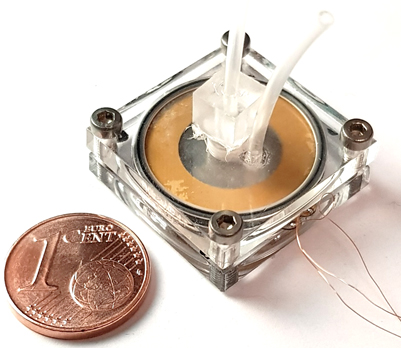

Tiny and highly complex: The micropump made by muVaP is 25 mm in size. Photo: muVaP

Buckle, don’t bend it: With this innovative idea, Ardavan Shabanian of the Department of Microsystems Engineering IMTEK at the University of Freiburg, plans to overhaul the market for micropumps and microvalves: “Their many advantages cannot be overlooked,” says the Microsystems engineer. Of all the University of Freiburg startups, his prospective company muVaP received some of the highest funding in the EXIST-Forschungstransfer funding program – nearly a million euros. “Our technology is unique and it will be successful,” says Hans Rainer Stork, muVaP’s business expert. Globally, this market is worth more than ten billion US dollars annually. In the next ten years, muVaP plans to make up at least 100 million of that. The company aims to make its miniature devices even more compact and higher-performance, more efficient and robust.

Working out of sight

Micropumps and -valves work where you can’t see them. “Everywhere we need to administer precise doses of liquids or gases,” Shabanian explains. In addition, they keep liquids in small cooling circuits in motion, such as those in computer processors and densely packed LEDs. The areas of application seem endless: Medical technology, measurement technology, analysis technology, process engineering, printing technology.

“I got the first idea for the new principle when I was applying for my doctorate,” Shabanian remembers. But how exactly does it work? Micropumps work with piezoelectric elements (PE). These move when an electrical voltage is applied to them. In micropumps, PE deforms thin diaphragms in such a way that a cavity is formed beneath them. This creates a low pressure area. It sucks in gases or liquids through an opening. If the electrical voltage drops, the elastic membrane flattens out again, pushing the contents of the cavity out through a second opening - and the micropump pumps. In conventional systems, a piezoelectric element bends. It is stuck to the membrane and bends along with it. Shabanian does something else - he installs the PE around the membrane. “It presses onto the sides so that the membrane buckles out.”

This construction has many advantages: A module made of PE plus membrane can also serve as a microvalve. The conventional construction requires two such units and a clean room for production. muVaP can do without all that. “Our system is easier to produce. We can develop variants for special applications much faster.” Furthermore, the micropump valve systems are more robust than traditional ones. These fail under pressure of just a few bar. But muVaP modules, can withstand several bar. Also unlike conventional systems driven by magnets, muVaP pumps are not disturbed by magnetic fields. They also make no noise, one-tenth of the energy and barely become warm. “Magnetic valves require cooling systems or cool-down phases,” Shabanian says. Not least, Shabanian’s invention is very compact in situations with high flow rates. Standard models with a size of 25 square millimeters pump a maximum of seven milliliters per minute. Even smaller muVaP pumps can move seven times that.

Micropumps and -valves work where you can’t see them - for instance, they ensure that computer processors don’t overheat. Photo: Annie Spratt/Unsplash

Micropumps and -valves work where you can’t see them - for instance, they ensure that computer processors don’t overheat. Photo: Annie Spratt/Unsplash

Building a team is “almost like getting married”

These advantages put paid to Stork’s plans. “Actually, I was wanting to retire,” he says. But then he met Shabanian. Stork thought his ideas were “perfect” and he joined muVaP. He took on responsibility for acquisition, sales, marketing, networking and finance. Stork has been founding, managing, restructuring, promoting and advising companies for 30 years - after training as a precision mechanic and IT engineer. For his part, Shabanian thinks this is perfect: “He understands the technology and has business experience.” Microsystems engineers Anjan Bhat Kashekodi as software and hardware developer and David Stork as product developer completed the four-person management team.

“Building this team was the biggest challenge,” says Shabanian. “It's almost like getting married.” After all, it was the most important thing in his life so far. Apart from the right qualifications, what counts most is how people get along - the chemistry. The university’s Gründerbüro showed Shabanian what options starting a company would give him. The university provides the company with office and laboratory space free of charge. “We get unlimited support,” says Shabanian. He is also pleased with the generous EXIST grant - and that six Master’s students are doing valuable work for muVaP.

Negotiations with investors have begun

The company is to be established in the next six months, Stork says. “As soon as we have orders.” Negotiations are underway, he says, and there are a number of interested parties, from as far away as Japan. But muVaP is still looking for the market segment in which it can really get going. The current focus is on industrial applications. “We plan to build specially tailored micropumps and valves,” says Stork. In order to become a significant market force here, muVaP must secure one-sixth of its sales. Hans Rainer Stork believes they can do that in five to eight years.

“After that, we aim to expand our product range into other applications and grow some more,” says Shabanian. He hopes to become a major player in several market segments. He has his eye on medical technologies. With energy-saving muVaP systems, long-term implants would last much longer, he reckons. “It would be great if we could improve the quality of life of patients.” In the meantime, he want to finish his doctorate on micropumps. He has already passed the research section with flying colors. Now he just needs a title.

Jürgen Schickinger