The Sky’s the Limit

Freiburg, Mar 08, 2017

Tethered airplanes that use airborne wind energy to generate electricity: Prof. Dr. Moritz Diehl and his team are developing mathematical models for simulating such systems on the computer. The goals are to achieve fully automated controls and maximum power output.

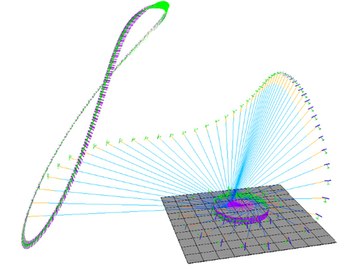

The metal arm rotates slowly at first, then faster and faster. An airplane with a wingspan of around two meters is attached to a thin tether, initially only about a foot from the end of the arm. The rotation lifts the plane onto its flight path. Now the winch below the metal arm starts unreeling the tether, causing the plane to fly in larger and larger circles. Finally, the rotating motion of the arm stops and the plane begins flying in a figure-eight pattern. This continues until the 600-meter-long tether is completely unreeled, and then the plane goes into a descent. The winch starts reeling the tether back in. The airplane makes a curve and returns to a figure-eight pattern. The winch starts unreeling the tether once again, and the cycle starts from the beginning, like a yo-yo.

6279273c3647e671f0ae084675373ad2

There are not yet any systems of this kind in operation today, but if Moritz Diehl succeeds in his aims, airborne wind energy will be used to generate electricity in just a few years. The Freiburg professor of systems theory, control engineering, and optimization is convinced that his airplanes, which fly through the air like fully automated stunt kites, are at an advantage in comparison to conventional wind energy systems. “Our airplane reduces a wind turbine to the wing tips, the part that rotates fastest and generates the most energy,” says Diehl. That saves material and thus money.

Strong, Steady Wind

In addition, the wind blows stronger and more steadily several hundred meters above ground than it does at ground level. Airborne wind energy systems are therefore capable of generating energy practically nonstop and do not even stand still when the wind calms down or comes from the wrong direction. Their yearly output is estimated to be at least twice that of wind turbines. The expectation is that they should thus be more efficient, make energy production less expensive, and help to reduce the price of electricity. The systems could potentially be built on land, but they make more sense on the sea: They need a free space with a radius of at least the length of the tether around the arm and the winch.

The Freiburg researchers have built a prototype of a rotating arm that launches a tethered airplane into the air to harvest energy. Photo: Patrick Seeger

Two systems for harvesting airborne wind energy are currently under development. One of them involves placing propeller-powered generators on board the airplane. The propellers make it easier to launch and steer the airplane, and there is no need for a rotating arm to get it off the ground. In addition, it can remain in a flight path that allows it to harvest a maximum amount of energy, instead of having to go into a descent between each cycle. However, the generator also makes the airplane much heavier. Moreover, it can no longer be attached to a simple tether but needs a cable to transmit the power to the ground.

Mathematical Models

These drawbacks are why Diehl is concentrating his efforts on the other system, described at the beginning of this article: The generator is located on the ground and harvests energy as the tether is reeled out during the airplane’s ascent. This requires alternating phases of ascent and descent. However, the net energy gain is still positive, explains Diehl: “Although we need to use some energy to reel the tether back in, it is still much less than what we gained as it was reeled out.” This system works with two types of aircraft: soft kites built like a paraglider and hard airplanes made of carbon composites. The kites are lighter but also slower, and the material of the thin sail membranes wears out more quickly. The faster airplanes produce more tensile force, but this also makes them more difficult to control.

This is the aspect Diehl is focusing on in his research: “We are simulating the systems with the goal of optimizing the controls to enable maximum power output.” A high power output is only possible if all of the parts and settings are meticulously coordinated: including the length and thickness of the tether, the speed with which it is reeled out, the size and shape of the airplane, and its flight patterns – and all of these factors need to be adjusted to the wind conditions at the site where the system is installed, which fluctuate over the course of the year. The team at the Department of Microsystems Engineering (IMTEK) develops mathematical models for these complex calculations and uses them to simulate the systems on the computer until they have found the ideal design. For example, the team determined in this way that the tether needs to be reeled out at one-third of the current wind speed to ensure a maximum energy harvest.

Light and fast: Airplanes made of carbon composites are ideally suited for use in airborne wind energy systems. Photos: Patrick Seeger

Light and fast: Airplanes made of carbon composites are ideally suited for use in airborne wind energy systems. Photos: Patrick Seeger

The entire system needs to have fully automated controls. This is particularly tricky in the case of takeoffs and landings. Diehl and his team have therefore built a prototype of the rotating arm. The design enables the researchers to collect precise data on the flight path of the tethered airplane that they can use to improve the simulation. The prototype is also equipped with sensors that collect data on things like the altitude and speed of the airplane or the direction and force of the wind at all times.

Another challenge involves keeping the airplane as close to the optimal flight path as possible after takeoff and compensating for turbulence. This is done by means of movable flaps. “It’s like when you’re driving a car with a side wind and need to correct for it by steering slightly into it,” says Diehl – except that the airplane needs to correct the steering on its own. This involves a capability the researcher refers to as “predictive regulation”: The airplane needs to be able to predict new situations and react before they arise.

100 Predictions per Second

A onboard computer first attempts to use the data collected by the sensors to estimate where exactly the airplane is located, how it is moving, and what the current wind conditions are like. For example, it registers sudden turbulence and calculates what the airplane can do in the next seconds to come as close to the ideal flight path as possible in spite of the disturbance. This leads to new data, to which the computer reacts again. The result is a control circuit: The planning is revised every ten milliseconds, 100 times per second. This makes the flight smoother and more stable.

However, the possibilities for influencing the airplane in this way are relatively modest, says Diehl. The most important factors for power output are the design of the system and the takeoff procedure. “The flight path of a ball also depends essentially on how large and heavy it is, how hard I throw it, and at what angle. Once it is in the air, it has its own dynamics.” What is important in any case is that the airplane does not hang statically in the air but flies in circles or figure-eights. This increases the tensile force many times over, as with a kite.

First circles, then figure-eights: This simplified representation shows the two figures the airplane flies in during its ascent. Illustration: Greg Horn

The scientist sees great potential in airborne wind energy systems. “One square meter of flight area can cover all the energy needs of two people with a European lifestyle. That is the power generated by 125 square meters of photovoltaic modules.” But he envisions even more powerful systems involving up to three airplanes revolving around a tether. This will increase the power output due to the higher tensile force, but it will also make it even harder to control the system and prevent the airplanes from getting in each other’s way.

Diehl is currently collaborating on two airborne wind energy projects: Highwind, for which he is receiving a Starting Grant from the European Research Council (ERC), and Awesco, a joint research project with eight scientific and four industrial partners that is also receiving European Union funding. The next biennial “Airborne Wind Energy Conference” will be hosted by the University of Freiburg from 5 to 6 October 2017. “Harnessing the power of airborne wind is an old dream of mine,” says Diehl. “I’m happy so many people are working on the topic now.”

Nicolas Scherger