Molecular Glue

Freiburg, Aug 01, 2018

They are lightweight thanks to new combinations of fibers, plastics, and coatings, enabling airplanes to save fuel and electric cars to improve their range. Jürgen Rühe, professor at the Department of Microsystems Engineering, is developing such recyclable materials at the Sustainability Center Freiburg.

Thanks to new combinations of fibers, plastics, and coatings, electric cars improve their range. Photo: lassedesignen, tiero/Fotolia

Prostheses, tennis rackets, automobiles, wind turbines: For many products that need to be both lightweight and stable, there is a trend toward fiber composite materials. They consist of a plastic, the so-called matrix, and particularly hard fibers made of materials like carbon, cellulose, or glass. The matrix covers up the fibers to make a robust composite material. But the interface between the two components is a weak point at which the material is likely to break when it is strained beyond a certain maximum load. A project at the “Sustainability Center” established jointly by the University of Freiburg and Freiburg’s five Fraunhofer institutes wants to find a solution to this problem: with the help of a new type of chemical coating developed by Jürgen Rühe, professor for the chemistry and physics of interfaces at the University of Freiburg’s Department of Microsystems Engineering (IMTEK). He is cooperating with the research group of Dr. Jörg Hohe at the Fraunhofer Institute for the Mechanics of Materials (IWM). The team is working on developing a more stable composite and improving the sustainability of the materials used.

Great Force, Tiny Cracks

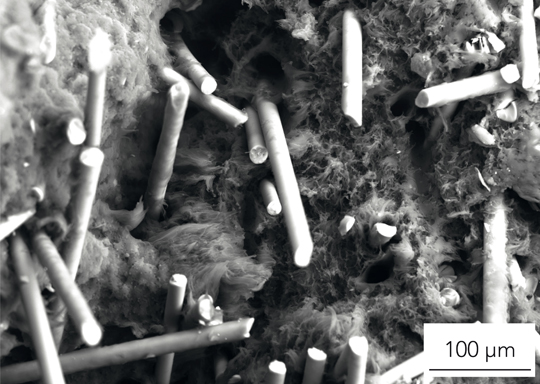

When a great force acts on a material – whether it be the blade of a wind turbine withstanding gusts of wind, a bicycle helmet exposed to shocks on bumpy trails, or a tennis racket hitting a ball – it can create microscopically tiny cracks. These cracks can continue to grow larger as the material is exposed to further strain, ultimately causing it to break. It is possible to prevent this from happening by reinforcing the plastics with high-strength fibers. When a crack hits a fiber that has been firmly embedded in the plastic in this way, the force is deflected diagonally to its original direction and scattered over a greater surface. “The energy that enters the material is scattered, the force at the edge of the crack is weakened, and a break is prevented,” explains Rühe. The fibers that achieve this effect have a diameter of only around ten micrometers, one-tenth the thickness of a human hair. In the case of short fiber materials, many individual fibers of about 200 micrometers in length lie crisscrossed in the plastic. “Such an arrangement makes sense when the force acting on the material can come from different directions,” says Rühe. If the direction of the force is more or less constant, however, long fiber materials are more suitable: The fibers of these materials can be several centimeters long, woven into a mat, and arranged perpendicular to the direction of the force.

However, there is still one weak point: In conventional fiber composites, the fibers are enclosed in the plastic, and the two materials stick to each other only through physical interaction. The interface between them, in other words precisely the point at which the incoming force is deflected, thus provides a point that is susceptible to cracks. The goal therefore consists in increasing the adhesive strength of the material, emphasizes Rühe: “We have developed a molecular glue that binds the fibers chemically to the matrix.” Breaking this type of bond requires much more force, making the composite better at withstanding loads.

Great versatility: Fiber composites are at the same time light and sturdy and are suitable for use in a wide range of products. Photos: pattilabelle, aapsky/Fotolia

A Perfect Link

Rühe’s adhesive coating is only about ten nanometers thick, approximately one ten-thousandth the thickness of a human hair. It consists of plastic molecules with reactive groups that form a chemical bond with the first other molecule they encounter – but only after they have been activated by means of heat or light. Producing it therefore involves three steps: “First we apply the coating to the fibers, then we cover them with plastic, and finally we activate the reactive groups,” explains Rühe. This results in a perfect link: The activated groups form chemical bonds with molecules within the coating, on the surface of the fiber, and on the surface of the matrix. “The fiber is given a kind of magic hood: The coating looks the same to the plastic as the plastic itself, and the bonds between the two are as stable as those within the matrix.”

The novel process also has another advantage: If a fusible or soluble plastic is used, it is possible to separate it cleanly from the fibers again and recycle them. The next coating is then simply applied over the old one and links with it via chemical bonds. “It’s a bit like the floor polish you apply when parquet flooring becomes rough: The coating does grow over time, but since it is so molecularly thin in our fibers, it does not make a difference in relation to the overall dimensions of the fiber.” The fiber can then be embedded in a new matrix, while the removed plastic can be reprocessed.

To find out which combinations of fibers, plastics, and coatings produce the most efficient materials, Rühe is cooperating with the Fraunhofer Institute for the Mechanics of Materials in Freiburg. There a team begins by examining the properties of individual coated fibers – such as how evenly the coating is applied and how well it sticks. Then the scientists conduct experiments on individual fibers in which the matrix is represented by a single plastic drop. The point is to clarify issues like when the fiber breaks as forces act on the drop and what the surface of the break looks like. Third, the team produces samples of composites containing many fibers and observes how the materials behave under stress. “This allows us to see at various levels where we need to make adjustments to improve the performance of the material,” Rühe sums up. The first combinations that enable high performance have already been identified and are ready for use.

Crack in a long fiber reinforced plastic: The researchers observe in experiments how the composites behave under stress. Photo: Fraunhofer Institute for the Mechanics of Materials

Sustainable Materials

The fiber composites from the research project are therefore sustainable in several respects: They can be recycled, their improved properties enable products to achieve the desired performance with less material – and if they help to reduce the weight of cars or airplanes, they also help to save fuel. The materials are particularly interesting with regard to electric cars, says Rühe: “Lighter vehicles have a significantly greater range. It would be a big step to make an axle for a car from a fiber composite material – those made of iron weigh ten times as much.” The materials can also play an important role in power generation: The lighter the blade of a wind turbine is, the more energy it can harvest, because it needs less wind to power it.

However, Rühe emphasizes that the new coating is not just suitable for fiber composites. “We want to provide a chemical tool that is capable of combining a variety of materials together.” At the same time, he is delighted to have the opportunity to use the molecular glue in lightweight construction and thus make more sustainable products possible: “This focus on applications is what makes our cooperation with colleagues at the Fraunhofer Institute at the ‘Sustainability Center Freiburg’ so attractive.”

Nicolas Scherger