Award-winning measuring technology at a nano scale

Freiburg, Apr 23, 2020

The Freiburg research team headed by Prof. Dr. Peter Woias of the Department of Microsystems Engineering (IMTEK) together with a team headed by physicist Prof. Dr. Saskia F. Fischer from Berlin’s Humboldt University has been awarded the Helmholtz Prize. The prize is seen as one of the most significant international awards in the field of metrology, the science of precise measurement. The group has succeeded in creating the necessary technical conditions for standardized precision measurement of the thermoelectric characteristics of individual nanostructures. The Helmholtz Fund has honored this achievement with the prize in the category of “applications” which brings with it 20,000 euros.

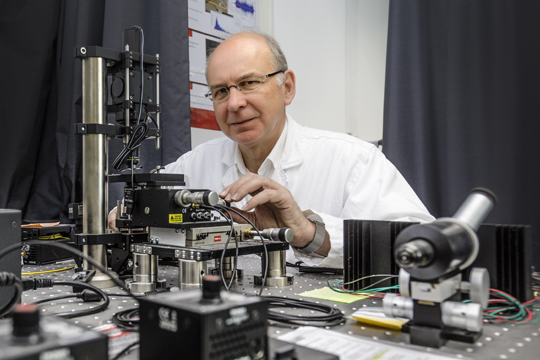

Peter Woias researches at a nano scale – and always keeps real-life applications in mind. Photo: Jürgen Gocke

Peter Woias researches at a nano scale – and always keeps real-life applications in mind. Photo: Jürgen Gocke

“It’s a great prize,” says Peter Woias. “I’m extremely proud about it, especially for the young researchers from my team – Dr. Zhi Wang, Dr. Johannes Ruhhammer and Dr. Michael Kröner – and from the Berlin team – Maximilian Kockert, Dr. Danny Kojda, Dr. Rüdiger Mitdank and Dr. Anna Mogilatenko. The Helmholtz Prize honors the work of a group, and its driving force is the doctoral students and the postdocs.” It was only possible to carry out this work because two teams with different orientations worked together – the Freiburg team on the microtechnology side and the construction of microapparatus and the Berlin team with the metrological setups and the background in physics. “It wouldn’t have worked out without this.”

The metrological study stems from a priority program investigating nanostructured thermoelectrics funded by the Deutsche Forschungsgemeinschaft (DFG). Many of us know the phenomenon of thermoelectrics from camping. For a cool drink, we link up a Peltier refrigerator to our car battery. Then, put simply, the electricity makes one side of the Peltier element hot and the other, where the drink is stored, nice and cold. “We’re studying it the other way round,” says Woias. “That is, you can also keep one side hot and the other cold, and this gives rise to electrical energy in the thermocouple. So we obtain electricity from heat differences or the flow of heat.” In this case, we talk of thermoelectric generators. People have thought for a long time that better efficiency can be achieved from conversion, if you produce the materials for these thermoelectric generators in nano structure size, that is, as a nanopowder, for example, which is injected into a larger body.

Tiny dimensions, better characteristics

“The theory indicates: if I make the dimensions of a thermoelectric material far smaller, then the thermoelectric characteristics improve,” explains Woias. “So our job here was to build a measuring platform that allows contacting our test object, an individual thermoelectric nanowire, via electricity and heat.” A wire like this has a diameter of about 100 to 200 nanometers and is sometimes only 20 micrometers long – a quarter of the diameter of a human hair. At these dimensions there are no simple electrical terminals. For this they use a special measuring platform, a silicon chip, which has been developed and improved several times in Freiburg over the course of two doctoral theses so far.

Woias conveys a clear impression of how complicated it is to work in the nano range. It starts with the production of the nanowires, which are synthesized chemically: “In the end you have a black cloud in a glass with ethanol, which has to be thinned down so that there aren’t too many wires swimming in it. Next a single nanowire has to be fished out of this solution and placed precisely on the silicon chip. We’ve dreamed up various processes for doing this. Finally we still have to connect it electrically and thermically to the silicon chip. We’ve developed a suitable process for this too.” The devil is in the detail!

Electricity from waste heat

So is all this effort worthwhile? The answer to this was the objective of the fundamental research and technology development for the measuring platform. “Even just measuring one single characteristic on a nanostructure is a challenge. We got the Helmholtz Prize because our measuring chip can precisely determine not just one but several dimensions on one and the same nanowire. And the measurement results of our Berlin colleagues were verifiably good,” says Woias. The better the thermoelectric characteristics of materials, the smaller and more efficient future thermogenerators made of these materials will be. This makes small energy self-sufficient sensor systems possible, which is not only relevant to the Internet of Things, but almost anywhere that data needs to be collected. For instance, radio sensors powered by waste heat could easily be stuck to a warm surface and start to work. No need for power cables, and replacing expensive batteries is unnecessary.

However, the measuring platforms for nanowires developed by Woias’ group also enable new discoveries on structural effects in the nano range. The function of the form is determined at a nano level. The structure determines, for instance, how elastic the wires are. “On another project we laminated silver nanowires on a surface into a networks. Optically it is transparent, because the wires are so thin, but electrically conductive. Optimal for any touchscreen,” says Woias. If the surface can also be elastic, then no end of human-machine interfaces are conceivable, Such as smart gloves that measure finger movements. “We’re currently building an adjustable lens with it.”

Creative lateral thinking

But despite all the fundamental research, it’s always important to Woias to keep real-life applications in mind. One essential element of this, he believes, is interdisciplinary cooperation, “We enjoy thinking and working with other disciplines, and most of the projects that we carry out in our department are based on cooperations with chemists, biologists, philosophers, psychologists, engineers or physicists. On the one hand it’s very exciting, on the other lateral thinking across disciplines promotes the creativity of everyone involved – and new ideas and applications suddenly appear.”

Jürgen Reuß